Technology of Phase Change Material

Everything you need to know about phase change material

Technology of phase change material

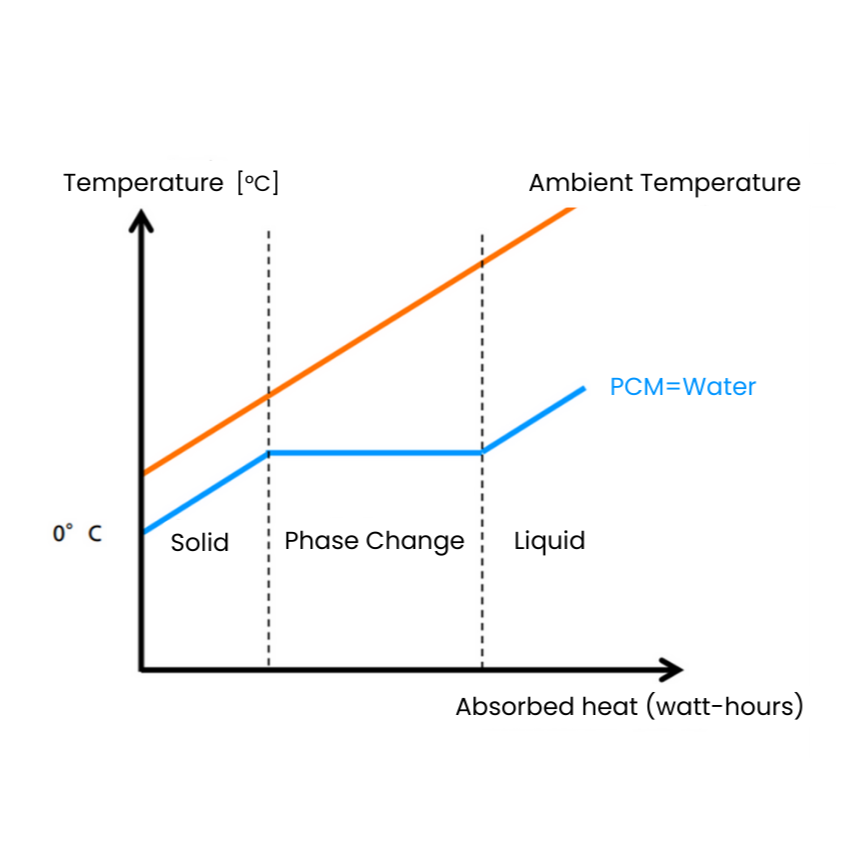

Phase change materials (PCMs) are substances that store and release heat through changes in their physical state (e.g., from solid to liquid or vice versa).

When learning about phase change materials, their key characteristic stands out:

• When the ambient temperature rises above a specific threshold, the material absorbs heat and changes state, preventing the surrounding temperature from rising too high.

• When the temperature drops below this threshold, it releases stored heat and reverts to its original state, stopping the surroundings from getting too cold.

This cycle of heat absorption and release—central to understanding about phase change materials—naturally maintains stable temperatures, acting like a “temperature regulator” that requires no electricity.

How Do Phase Change Materials Work?

- A simple example illustrates this:

When transporting ice cream, if phase change materials (set to change state around 0°C) are placed in the insulated container, they will absorb heat and transition from solid to liquid as the external temperature rises. This keeps the container’s interior near 0°C, slowing the ice cream’s melting. When the external temperature drops, the material releases heat and solidifies, continuing to stabilize the temperature. - Through this heat regulation during state changes, phase change materials can maintain stable ambient temperatures more effectively than ordinary insulation.

Key Advantages of Phase Change Material

- Precise temperature control:

- Unlike ordinary insulation (e.g., foam, thermal cotton), which only slows heat transfer, PCMs can stabilize temperatures within specific ranges (e.g., 2–8°C, 0–5°C), meeting strict temperature requirements for pharmaceuticals, fresh produce, and more.

- Reusable:

- After absorbing heat, PCMs can revert to their original state with simple cooling (e.g., refrigeration) and be reused dozens to hundreds of times, reducing long-term costs.

- Energy-efficient:

- No external power is needed. By passively regulating temperature, they reduce the operating frequency of air conditioners and refrigeration equipment, indirectly saving energy.

- Flexible applications:

- They can be made into plates, gels, films, etc., adapting to installation and usage needs in various scenarios.

Trending Applications of Phase Change Material

Frequently Asked Questions

Q: Is phase change material safe?

- A: Commercial PCMs mostly use cosmetic or food grade raw materials or inert components. They are non-toxic, non-corrosive, and meet safety standards, making them suitable for scenarios involving human contact or food.

Q: What is the service life?

- A: Under normal use, PCMs can function stably for 4000~20,000 cycles, depending on the PCM types, maintaining good performance even after thousands of state changes.

Q: How to choose the right phase change material?

- A: Selection primarily depends on the required temperature range for the application (e.g., 2–8°C for pharmaceutical transport), combined with factors like latent of heat, space constraints and reuse frequency.

Address List

- #707 Jia Qian Road Nanxiang, Jiading Shanghai, China

- +86 13301781710

- info@pcmcool.com

Social Networks

- Shawn Lee

- 86-13301781710